American workers have become accustomed to their employers shutting down manufacturing capacity in the US as they set up operations in low-wage locations. Now this ‘race to the bottom’ has hit Germany in a very visible way. After years of mismanagement that resulted in poor-quality automobiles and red ink, General Motors announced massive layoffs at its German Opel facilities. Mark Landler at the New York Times reports:

“G.M., which owns Opel, has begun negotiations with union representatives at all its European plants over a cost-cutting plan that is aimed at saving 500 million euros ($623 million) a year in labor costs, and could result in a reduction of up to 12,000 jobs, most in Germany.

In Bochum, a gritty industrial city in the Ruhr Valley, workers are demanding that G.M. guarantee it will not lay off workers or shut the factory. The plant, which employs 10,000, is considered particularly vulnerable as G.M. weighs moving production to lower-cost sites in Eastern Europe.”

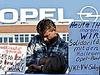

But then somthing interesting happened. Unlike workers in the US who meekly receive their pink slips and then apply for low-paying Mcjobs at the local Wal-Mart, the Opel workers decided to take responisiblity for their own future and began a wildcat strike. Such a move is highly unusual in Germany, which for decades has relied on consensus between the trade unions and management to keep worker unrest at bay. And the strike at Opel/Bochum did not have the approval of either IG Metall, the giant union that represents German autoworkers, of the plant Workers’ Council (Betriebsrat) that negotiates directly with plant management.

Despite threats of massive reprisals by GM, the workers in Bochum have continued their illegal strike for six days. And there were signs that their action was beginning to produce results. From today’s Boston Globe:

“In a conciliatory sign, Opel said yesterday that it had agreed with employee delegates to try to ensure the survival of its main plants in Germany — including Bochum — beyond 2010, while finding “socially acceptable” ways of cutting back the workforce.

Opel said a shortage of parts from Bochum stopped production yesterday at Ruesselsheim and in Antwerp, Belgium. Company spokesman Ulrich Weber said Bochum usually produced about 1,000 cars a day, while Ruesselsheim made nearly 900 and Antwerp around 1,100. “

The situation at Opel has been examined extensively in the German Press. The German economy is higly dependent on automobile production: one out of every seven jobs is in the auto sector. And management has found ways to achieve the same much-admired German productivity and quality in foreign markets.

Lange konnten die deutschen Arbeitnehmer in Anspruch nehmen, besonders produktiv zu arbeiten. So konnten sie den Lohnkostenvorteil ausländischer Konkurrenten ausgleichen. Doch dieser Vorteil schwindet. Das gilt vor allem für die Autohersteller. Die haben längst gelernt, überall in der Welt die deutschen Produktionsstandards zu erreichen.

Das macht die Entscheidung von GM so gefährlich. Deutschland lebt von der Fahrzeugindustrie. Jeder siebte Arbeitsplatz hängt vom Auto ab. Gewerkschaften und Politiker sollten aufhorchen. Andere werden sich ermutigt fühlen, GM nachzuahmen.

But does this have to be the long-term fate of Opel production in Germany. Yesterday the strikers were paid a visit by the Betriebsrat of Porsche. Ten years ago Porsche was on the verge of bankruptcy; today Porsche is the most profitable auto-producer in the world.

UPDATE: After the Bochum strike effectively stopped all pruduction in Germany, Belgium, and at the GM plant in Liverpool, the workers agreed to end the strike and gave the Betriebsrat permission to commence negotiations with Opel management